Scroll to:

Situational analysis on porcine diseases of priority to pig industry: methods for biosecurity improvement in the Russian Federation holdings

https://doi.org/10.29326/2304-196X-2024-13-4-396-404

Abstract

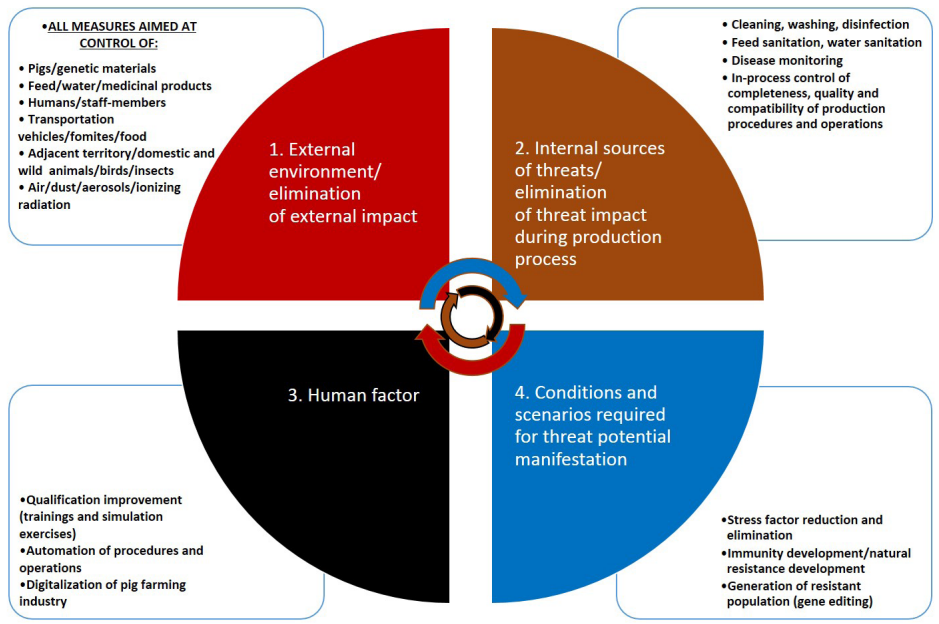

The analysis of the situation on management of main epizootic threats significant for pig industry in the Russian Federation was carried out. The features and effectiveness of various biosecurity measures used in pig holdings and possible ways for their improvement were examined. Options for improvement of biosecurity measures in Russian pig holdings and development of the systems in the Russian Federation having favorable effect on the population protection were discussed focusing on four target aspects related to infection introduction and spread routes: isolation of the population from external sources of threats (elimination of probable environmental impact scenarios); isolation of the population from internal sources of threats (elimination of probable impact scenarios during production process); isolation of the pig population or pig farming system from the human factor impact (elimination of possible scenarios of human factor impact on the population); isolation of the population from the conditions under which the threat potential is manifested (changing of conditions). The analysis results were presented graphically in the form of a schematic diagram“Sources of threats to biosecurity systems and measures aimed at these sources for the protected population creation in pig industry”. Based on the discussion results, automation and digitalization of all processes in pig industry, generation of genetically modified pigs not susceptible to the most significant pathogens such as African swine fever, classical swine fever, porcine reproductive and respiratory syndrome viruses and their use for production purposes, further research and implementation of integrated technological solutions for feed sanitation have been concluded to be the evolutionarily significant ways for effective pig farming intensification in the Russian Federation.

Keywords

For citations:

Oganesyan A.S., Shibayev M.A., Petrova O.N., Baskakova N.Ye., Karaulov A.K. Situational analysis on porcine diseases of priority to pig industry: methods for biosecurity improvement in the Russian Federation holdings. Veterinary Science Today. 2024;13(4):396-404. https://doi.org/10.29326/2304-196X-2024-13-4-396-404

INTRODUCTION

Pork remains the main source of animal protein in the world, its output annually exceeds the production of meat of any other type. In 2019–2020, global animal protein production declined sharply due to large-scale outbreaks of African swine fever (ASF) in China and Southeast Asian countries. The Russian Federation has become self-sufficient in pork since 2020, and in 2022, commercial holdings produced 5,275.1 thousand tons of pork (slaughter weight), and proportion of large holdings was 76%. According to the predictions, domestic pork consumption will remain high and continue to grow up to 2025 in the Russian Federation [1][2]. Pigs are susceptible to a wide range of diseases that affect their performance and pig producers’ income. The spread of porcine diseases in the Russian Federation had a significant negative impact on pork production in the country during the last 10 years (since 2013), when, according to official data from the World Organization for Animal Health (WOAH), (214,985 ± 165,558) domestic pigs were annually destroyed due to ASF only with peak in 2020, when 615,239 pigs were destroyed. The ASF epizooty has been effectively contained for all these years owing to the coordinated joint activities of both State Veterinary Service with Regional Administrations and in-house veterinary staff with the holding managers as well as all pig holding sites. At the same time, any biosecurity system cannot be established based on template solutions only and is developed taking into account the holding characteristics, animal rearing practice, climatic conditions, animal disease situation in the region, sources of raw materials and feed. However, in any case, the biosecurity system consists of two components. External biosecurity is aimed at prevention of pathogen introduction into the herd, and internal biosecurity is aimed at prevention of the disease spread within the herd or production system. The study of the epizootic patterns of porcine diseases in pig industry and prioritization of porcine diseases allow for development of adequate biosecurity measures for the pig sector [3][4].

In this context, description and assessment of options for the biosecurity system evolution in holdings remain an urgent task in the framework of discussion on organization of biosecurity measures and ways for their improvement for pig holdings and pig rearing systems in the Russian Federation.

MATERIALS AND METHODS

Official information on measures against porcine diseases taken in the country, scientific literature data, data from open official sources, special round tables and the mass media were used. The measures were assessed and discussed using elements of risk analysis and expert assessment with the consensus achievement [5]. The options for biosecurity measures improvement in pig holdings/pig rearing systems in the Russian Federation that could have impact on pig population protection were discussed taking into account four target areas related to the infection introduction and spread routes.

- Isolation of the population from external sources ofthreats (elimination of probable environmental impact scenarios).

- Isolation of the population from internal sources ofthreats (elimination of probable impact scenarios during production process).

- Isolation of the pig population orpig farming system from the human factor impact (elimination of possible scenarios of human factor impact on the population).

- Isolation of the population from the conditions under which the threat potential is manifested (changing of conditions).

The analysis results were presented in the form of a schematic diagram “Sources of threats to biosecurity systems and measures aimed at these sources for the protected population creation in pig industry” (Fig.).

Fig. Schematic diagram “Sources of threats to biosecurity systems and measures against these sources for protected population creation in pig industry”

RESULTS AND DISCUSSION

There are quite a few scenarios for known transmission routes for various porcine pathogens. Therefore, a set of standard potentially effective measures aimed at epizootic chain breaking could be provided for the most diseases. But there is no common universal biosecurity system for holdings. An effective system is created with the participation of veterinarians and other specialists who have complete information about the holding, processes, employees and risk factors. The biosecurity plan is unique for each pig holding and includes prioritization and succession of measures based on their potential effectiveness and appropriateness for the production process [4][6]. Quantitative data on each route or element impact and relative importance for the transmission scenario implementation are always required for development of point-based technological solutions. The actual effectiveness of applied biosecurity measures is influenced by economic, sociological and even psychological factors as well as their harmonization with the governmental official disease surveillance policy [7], that can be taken into account as negative factors or used for development of policies for biosecurity measures correction in holdings.

Biosecurity system strengthening in holdings is aimed at:

- Isolation of thepopulation from external sources of threats. Since domestication of pigs (about 10,000 years ago) [8] isolation of pig population from aggressive environmental factors has been historically the first effective measure used by humans in pig farming.

In an evolutionarily short period, the development of technical means and methods for pig population isolation from the external environment and the emergence of more and more modern technologies in pig farming industry (in genetics and artificial insemination; feed production; pharmacology and vaccinology) had enabled development of industrial pig production strategies and concentration of up to 84,000 sows producing over 2 million pigs per year in megaholdings by 2020 (in the People’s Republic of China). Industrial pig production has provoked changes in susceptible population features (genetic homogeneity of the population, immune homogeneity); had an effect on the prevailing pathogen transmission mechanisms (increased number of direct and indirect contacts, emerged iatrogenic risks, risks of pathogen spreading through artificial insemination, feed-associated risks, etc.); enabled accelerated pathogen evolution during the production process and in large populations (reassortment, including reassortment with vaccine strains; associated infections; antibiotic resistance; changes in the epizootiology of many infectious and non-infectious diseases, etc.).

The evolution of the epizootiological triad components has made traditional approaches to population segregation ineffective due to globalization of pathogen spread risks in industrial pig production systems and necessitated development of new tools – biosecurity system and compartmentalization, effective against both new pathogens and pathogens that have changed their epizootological characteristics [9].

There are infections new to pig industry such as the widespread porcine reproductive and respiratory syndrome (PRRS), ASF caused by the genotype II virus, porcine epidemic diarrhea (PED) and swine influenza, as well as recurrent infections – classical swine fever (CSF) and foot-and-mouth disease (FMD). Isolation of the population from the external environment in pig farming systems is found insufficient for agents of the above-mentioned infections, and, first of all, highly contagious pathogens (PRRS, FMD, swine influenza, CSF, ASF viruses, mycoplasmosis agent) that are transmitted by both direct and indirect routes

[10, 11, 12, 13, 14, 15].

Considering this, population isolation methods take the new level. For example, taking into account possible airborne transmission of PRRS virus in indoor pig keeping systems much attention is paid to use of air filters and other air filtration technologies for the population protection [16]. Some studies have shown that air filtration system installation on pig farms contributed to an 80% reduction of the risk of PRRS virus introduction into production systems [17][18].

It should be noted that Chapters 5.4, 5.5, 5.7 and 7.3 of the WOAH Terrestrial Animal Health Code [19] address to safe transportation of animals in isolated transportation vehicles preventing transboundary disease spread. It shows that likelihood of infection and pathogen spread during transportation shall be taken into account. Therefore, it is recommended to take into account meteorological risk factors associated with the presence of each of the pathogens in the air, as well as the ability of mechanical and antimicrobial filters to protect susceptible populations from RRRS virus and other pathogens for which aerosol spread has been proven (mycoplasma, swine influenza, CFS) in holdings and during transportation.

Compartmentalization (along with zoning) is also currently considered as a measure sufficient for creation of the population free from most transboundary diseases, including panzootic genotype II virus-caused ASF – a relatively new problem for global pig industry [9]. At the same time, fomites, transportation vehicles and animals (including rats, birds and insects) coming in contact with the pig population are considered to play important role in the “domestic cycle”. Therefore, measures for exclusion of scenarios of potential exposure environmental through transportation vehicles, fomites, mechanical carriers, etc. should be periodically reviewed. The main focus is shifted to discussion the reliability of control of sanitary measures aimed at the population isolation from the external environment and potential for automation of biosecurity systems in holdings (for example, online monitoring of in-house transportation vehicle movements between compartments, the integrity of the holding perimeter, protection against mechanical vector penetration and activities; control of cleaning, washing and disinfection quality in technical facilities and transportation vehicles using automated devices for residual contamination detection, etc.). Automated control will allow for improvement of biosecurity system and isolation measures effectiveness.

Automation and digitalization of systems for effective air filtration, microclimate maintenance and for their control in facilities as well as when animals arrive to the holding or moved between compartment sites using public roads running through rural territories are also the most modern isolation measures contributing to elimination of gaps in management of airborne infection risk (primarily PRRS and mycoplasmosis).

The assessment of measures for segregation control in biosecurity systems and the experience accumulated by holdings in this field are of scientific interest for development of basic recommendations to put them into practice.

- Isolation of thepopulation from internal sources of threats. Likelihood of such threats affecting pigs during production process is eliminated by monitoring the completeness, quality and consistency of procedures and operations used within the production (technological) chain (in-process control). This also includes internal quarantine when moving adult animals between groups, and the “all in – all out” approach, sanitation and containment measures, etc. However, we will focus on three independent areas.

Cleaning, washing, disinfection. Management of risks of pathogen introduction and spread in herds through production chain is based on both general measures for holding biosecurity ensuring and targeted techniques to control the effectiveness of measures taken. Hygiene management is becoming increasingly important as an independent biosecurity tool. Infectious activity of most porcine viral and bacterial pathogens can be significantly reduced as early as at the cleaning stage, where up to 90% of microorganisms are destroyed that significantly increases the effectiveness of further disinfection [20] and facilitates elimination of scenarios of probable exposure during production process by “cutting off” probable indirect contacts. Therefore, the triad components: “cleaning – washing – disinfection” in processes where they are applied (treatment of transportation vehicles, footwear, equipment, facilities, etc.) should be as one measure (a three-stage process that includes sequential cleaning, washing and disinfection), and each operation should be subject to control.

In-process monitoring of pathogens. Porcine factor pathogens are characterized by circulation in herds with clinical disease cases manifesting only in isolated sex and age groups of animals (porcine parvovirus and rotavirus infections, actinobacillosis pleuropneumonia, streptococcosis, salmonellosis, pasteurellosis, escherichiosis, leptospirosis), therefore, control of measures against such infections can be focused on isolation of animal subpopulations during production process for a period of time sufficient for immunity (resistance) development [21, 22]. Consequently, the production processes for different groups of pigs should be monitored and such monitoring should be the part of a biosecurity plan. In addition, in-process monitoring based on serological tests with the mandatory use of polymerase chain reaction followed by sequencing of the detected isolates allowing for accurate determination of subpopulations status and potential scenarios for the pathogen spread in the system is to be carried out at all points critical for pathogen transmission, for example, for PRRS virus (replacement animals, genetic material, transfer of animals from one group to another, control of “all in – all out” system operation). This will ensure in-process isolation of the subpopulation.

Feed sanitation. Sanitation of feed for pigs is the third key point in biosecurity programs of establishments for reducing likelihood of threat scenarios during production process [23-26]. Despite the fact that feeds can be produced by methods ensuring pathogen destruction, they are often cross-contaminated during storage, transportation or feeding. Some studies have shown long-term persistence of following infectious viruses in the feed during its transatlantic transportation: foot-and-mouth disease virus, ASF, swine vesicular disease virus, Aujezsky’s disease virus, PRRS, and porcine vesicular exanthema virus, whereas there is no evidence of such long-term survivability for CFS, Nipah, and swine influenza viruses [27].

The main measures for feed sanitation currently discussed worldwide are: 1) monitoring of feed directly supplied to pigs for pathogens; 2) holding of components of animal origin to decrease virus titre; 3) monitoring of feed and feed additive storage conditions; 4) application of additives (based on formaldehyde, fatty acids, essential oils and organic acids) for feed and water decontamination for bacteria and viruses removal (including ASF, PED virus), as well as application of mycotoxin adsorbents [23][26].

Therefore, feed sanitation should include, among other things, supplier reliability control, raw material quality control and measures for mitigation of such risks as: a) presence of pathogens in source materials; b) the presence of infectious agents in ready-to-use feed and high-risk feed components (components of animal origin); c) recontamination of finished feed during its production, transportation and storage [24].

- Isolation of thepopulation from human factor effect. There are no commercial pig herds in the world that are 100% isolated from the human factor associated with production process maintenance, from engineering aspects up to control of technological processes, including veterinary and zootechnical aspects. It should be noted that the human factor is one of the most difficult to control, but at the same time one of the key factors for effective prevention of infection introduction and spread.

Automation and digitalization in pig farming sector. The strategy for reducing the human factor impact is the most knowledge-intensive and rapidly growing area of the developing biosecurity system management. With the advent of new information technologies and technical capabilities, this area has been further developed into the whole separate segment called “precision animal farming”, that is widely discussed from the scientific and applied point of view in the pig breeders’ community as a promising practice for future production [28-33]. The priority task of the science today is to fill gaps in new technical solutions due to the complexity of validation of technologies for assessing affective states in pigs (both positive and negative) evaluated in process control systems using data obtained from recording sensors (strain gauges, thermal imagers, microphones, photometers, infrared, radio frequency sensors), as well as to reduce the cost of these technologies [34][35].

Automation and exclusion of the human factor impact on such processes as animal movements, control of crossing dirty and clean zones, assessment of cleaning, washing and disinfection effectiveness, microclimate control, weighing of animals, feed distribution, monitoring of the clinical state of animals (body temperature, behavior, feed and water consumption) are undoubtedly of high importance for qualitative improvement of biosecurity systems in the holdings in future.

Technological innovations have the strongest positive impact on production. The territories of the Russian Federation with the highest technological innovation level hold leading positions as for index of agricultural production [36]. Ministry of Agriculture of the Russian Federation is going to introduce digital technologies into the national agricultural sector, develop a platform for domestic agricultural product promotion as well as launch modeling and predicting systems (“Digital Agriculture”) by 2030. Obviously, advent of predicting technology allowing for creation of predictive models for animal diseases will enable a breakthrough in this area.

In other words, with data accumulation, it will become possible to create a basis for predictive models in existing pig farming systems allowing individual management decision-making modeling and predicting the response of all related estimated system indicators to these decisions, thereby reducing managerial errors at the stage of their development.

The expert community notes that the main consumers of new technologies in Russian pig farming industry are limited by top 50 pig producers. This is accounted for lack of funds and insufficient personnel qualifications and skills, the factors that impede large-scale automation and digitalization of pig farms. Small farms remain at the technological level of the last century. In Russian pig farms, veterinary manipulations account for large proportion of manual labor. Automation of animal censuring and remote diagnosis is in little demand, as it requires significant re-equipment of facilities and financial investments. Most of the technological processes in pig farming sector have been already mechanized, and currently they require automation. Full automation of production process on a smart farm is theoretically and practically possible, but it is still economically non-profitable [36, 37, 38].

The main challenge for domestic developers today, in our opinion, is the integration of systems of different producers put in place for various targets (microclimate control, feed control, control of hunting periods, livestock turnover, inventory, etc.) into common online management system, development and integration of automated systems for veterinary manipulations. Their creation and digitalization are carried out in consultation with experts and veterinary scientists, as this a priori will impact on the overall biosecurity level of holdings and will enable control of porcine infectious diseases in pig holdings [36-38].

Employee qualification improvement. Theoretically, the effectiveness of human factor elimination depends on the degree of the person involvement (awareness) in professional life and commitment to risk management practice in the field.

Continuous training and improvement of skills of the personnel involved in technological processes posing human factor – associated risks affecting committed implementation of biosecurity measures is an effective solution, as well as a measure complementing automation and digitalization of processes in pig farming industry. Trained personnel carrying out monitoring of each automated procedure, is the basis for the introduction of automation and informatization in pig farming sector.

Employee competence improvement throughout the whole production chain is the key aspect for elimination of barriers to digitalization, but also for reducing the impact of “advertising approach” to selection of measures and tools for disease prevention, when the ineffectiveness of medicines is masked by sales consultants with arguments about the imperfection of the applied preventive measures and tools and by requirements for the implementation of disease eradication programs that a priori are impossible at the level of a separate pig holding (refusal of vaccination, etc.).

- Isolation of thepopulation from the conditions under which the threat potential is manifested (changing conditions). The following is currently applied to exclude propagation and accumulation of pathogenic microorganisms: vaccination, acclimatization, the elimination of feed, heat, noise and behavioral stresses, breeding of animals resistant to pathogens and stress factors, changing of the design features/physicochemical properties of surfaces and materials coming in contact with pigs (floors, stalls, walls, bedding, drinking bowls, feeders, feed pipelines) [39].

Stress reduction/elimination. Type of feeding, type of microclimate in facilities where different age and sex groups are kept, and contamination of facilities are considered to be associated with the development of stress of various levels, morphological and biochemical changes in blood, changes in general animal resistance to stress and to pathogens, and animal performance, and the control of these parameters is akin to the control of factors contributing to unfavorable events [40-43]. Interdisciplinary approach has enabled generation of new materials and their introduction into pig production industry. Monitoring and management of animal keeping conditions and general resistance allow for reducing stress and neutralizing pathogen exposure, however, they are high-tech, knowledge-intensive and, as a rule, interdisciplinary areas for commercial pig farming.

Immunity development. Registered and approved vaccine shall be selected for vaccination taking into account genetic characteristics of the pathogen circulating in the region. Information about PRRS virus strain genotypes and the infection spread in the herd, for example, will help to timely select the most appropriate disease control strategy in the particular Russian Federation subject or production system [44, 45]. Application of vaccines against CSF and Aujezsky’s disease remains one of the most effective disease control measures and correlates with current biosecurity and biosafety measures used in pig farming industry in the Russian Federation. Improvement of animal health status involving the refusal of vaccination without the federal program and involvement of all regions and all business operators in the country appears to be ineffective based on the experience of other countries and in the context of current Russian Federation regionalization policy (the most effective quarantine tool in place in veterinary field in the Russian Federation).

Genetically modified pigs. Gene editing, which can be used for animal disease resistance inducing and maintaining is the most effective out of all measures that radically changes conditions in the pig farming system. In view of successful experiments in public health sector (HIV, sickle cell anemia and cancer of various types), gene editing technology is considered to have a great potential in animal disease treatment and prevention. This is, theoretically, generation of genetically modified pigs not susceptible to ASF or PRRS [46][47]. In case of any successful genetic improvement, it will only take just a few time to reproduced genetically enough virus-resistant progenitor pig populations to meet global demand.

CONCLUSION

Biosecurity of pig production systems is currently paid much attention in science and practice. The adequacy of the assessment and monitoring of external threats is a priority task for ensuring effective pig farming system biosecurity. The surveillance system, as the basis of all animal disease control measures already taken and implemented, should provide the pig industry and biosecurity systems of holdings with, first of all, accurate, measurable and interpretable data on the population state and existing external threats.

An important gap in the most technological solutions is the dependence on foreign software programs for equipment despite the presence of Russian developers on the market.

Taking into account the lack of standard technologies for pig farming sector and attempts to integrate equipment and software from different countries into a single project, the elimination of the “advertising approach” (unjustified transfer of some digital technologies from cattle farming to pig farming sector) is also the task for domestic developers of equipment and software programs (systems).

Employee competence improvement throughout the whole production chain is the key aspect for elimination of barriers to digitalization as well as for reducing the impact of “advertising approach” to selection of measures and tools for disease prevention when the inefficiency of medicines is masked by sales consultants with arguments about the imperfection of the applied preventive measures and tools and by requirements for the implementation of disease eradication programs that is a priori impossible at the level of a separate pig holding (for example, refusal of vaccination, etc.).

It can be concluded that the automation and digitalization of all processes in pig industry, creation of genetically modified pigs not susceptible to the most significant pathogens such as African swine fever, classical swine fever, porcine reproductive and respiratory syndrome viruses and their use for production purposes, further research and implementation of integrated technological solutions for feed sanitation are the evolutionarily significant ways for effective pig farming intensification and that they will facilitate the development of production data monitoring and porcine disease control systems and reduce the impact of manual control errors.

References

1. Plaksin I. E., Plaksin S. I., Trifanov A. V. Trends and prospects of pig breeding development in Russia. AgroEcoEngineering. 2022; (1): 155–168. https://doi.org/10.24412/2713-2641-2022-1110-155-168 (in Russ.)

2. Belaya A. Virusy prodolzhayut pod’’edat’marzhu. Myasnaya otrasl’terpit ubytki iz-za ukhudsheniya epizooticheskoi situatsii = Viruses continue to eat up margins. The meat industry is suffering losses due to the animal disease situation deterioration. Agroinvestor. 2022; (2). https://www.agroinvestor.ru/markets/article/37496-virusy-prodolzhayut-podedat-marzhu-myasnaya-otrasl-terpit-ubytki-iz-za-ukhudsheniya-epizooticheskoy (in Russ.)

3. Good practices for biosecurity in the pig sector – Issues and options in developing and transition countries. FAO Animal Production and Health. No. 169. Rome: FAO; 2010. 79 p. https://www.fao.org/4/i1435e/i1435e00.pdf

4. Kulikov S. P. Internal and external biosecurity in a modern pig farm. Pigbreeding. 2021; (4): 45–47. https://elibrary.ru/lewheg (in Russ.)

5. Oganesyan A. S., Gulenkin V. M., Karaulov А. К. Methodical guidelines for risk identification, assessment and management during live animal and animal product export and import. Vladimir: Federal Centre for Animal Health; 2013. 119 p. (in Russ.)

6. Titov M. A., Karaulov А. К., Shevtsov A. A., Bardina N. S., Gulenkin V. M., Dudnikov S. A. Methodical guidelines for assessment of the biosecurity in pig holdings in the Russian Federation. Vladimir: Federal Centre for Animal Health; 2010. 53 p. (in Russ.)

7. Alarcón L. V., Allepuz A., Mateu E. Biosecurity in pig farms: a review. Porcine Health Management. 2021; 7:5. https://doi.org/10.1186/s40813-02000181-z

8. Ottoni C., Flink L. G., Evin A., Geörg C., De Cupere B., Van Neer W., et. al. Pig domestication and human-mediated dispersal in western Eurasia revealed through ancient DNA and geometric morphometrics. Molecular Biology and Evolution. 2013; 30 (4): 824–832. https://doi.org/10.1093/molbev/mss261

9. Pfeiffer D. U., Ho H. P. J., Bremang A., Kim Y., OIE team. Compartmentalisation Guidelines – African Swine Fever. Paris: World Organisation for Animal Health; 2021. 148 p. https://www.woah.org/app/uploads/2021/10/asf-biosecuritychecklist-compartmentalisation-en.pdf

10. Blome S., Staubach C., Henke J., Carlson J., Beer M. Classical Swine Fever – An Updated Review. Viruses. 2017; 9 (4):86. https://doi.org/10.3390/v9040086

11. Havas K. A., Makau D. N., Shapovalov S., Tolkova E., VanderWaal K., Tkachyk T., et al. A molecular and epidemiological description of a severe porcine reproductive and respiratory syndrome outbreak in a commercial swine production system in Russia. Viruses. 2022; 14 (2):375. https://doi.org/10.3390/v14020375

12. Dixon L. K., Stahl K., Jori F., Vial L., Pfeiffer D. U. African swine fever epidemiology and control. Annual Review of Animal Biosciences. 2020; 8: 221–246. https://doi.org/10.1146/annurev-animal-021419-083741

13. Brown E., Nelson N., Gubbins S., Colenutt C. Airborne transmission of foot-and-mouth disease virus: a review of past and present perspectives. Viruses. 2022; 14 (5):1009. https://doi.org/10.3390/v14051009

14. Oganesyan A. S., Baskakova N. Ye., Shibayev M. A., Scherbinin S. V., Savvin A. V., Shevtsov A. A., Karaulov A. K. Detection of gaps laying the ground work for the introduction of transboundary diseases through passengers’ luggage. Proceedings of the Federal Centre for Animal Health. 2020; 17: 115–142. https://elibrary.ru/invxyc (in Russ.)

15. Desrosiers R. Transmission of swine pathogens: different means, different needs. Animal Health Research Reviews. 2011; 12 (1): 1–13. https://doi.org/10.1017/s1466252310000204

16. Dee S., Otake S., Deen J. Use of a production region model to assess the efficacy of various air filtration systems for preventing airborne transmission of porcine reproductive and respiratory syndrome virus and Mycoplasma hyopneumoniae: results from a 2-year study. Virus Research. 2010; 154 (1–2): 177–184. https://doi.org/10.1016/j.virusres.2010.07.022

17. Alonso C., Murtaugh M. P., Dee S. A., Davies P. R. Epidemiological study of air filtration systems for preventing PRRSV infection in large sow herds. Preventive Veterinary Medicine. 2013; 112 (1–2): 109–117. https://doi.org/10.1016/j.prevetmed.2013.06.001

18. Dee S., Cano J. P., Spronk G., Reicks D., Ruen P., Pitkin A., Polson D. Evaluation of the long-term effect of air filtration on the occurrence of new PRRSV infections in large breeding herds in swine-dense regions. Viruses. 2012; 4 (5): 654–662. https://doi.org/10.3390/v4050654

19. WOAH. Terrestrial Animal Health Code. https://www.woah.org/en/what-we-do/standards/codes-and-manuals/terrestrial-code-online-access

20. Scollo A., Perrucci A., Stella M. C., Ferrari P., Robino P., Nebbia P. Biosecurity and hygiene procedures in pig farms: effects of a tailor-made approach as monitored by environmental samples. Animals. 2023; 13 (7):1262. https://doi.org/10.3390/ani13071262

21. Shakhov A. G., Anufriev A., Anufriev P. Faktornye infektsii svinei = Porcine factor infections. Animal Husbandry of Russia. 2005; (Suppl.): 24–27. https://elibrary.ru/zjuyyr (in Russ.)

22. Prudnikov S. I. Factor infectious diseases of pigs and preventive measures. Siberian Herald of Agricultural Science. 2007; (6): 74–80. https://elibrary.ru/hfbgmi (in Russ.)

23. Niederwerder M. C., Dee S., Diel D. G., Stoian A. M. M., Constance L. A., Olcha M., et al. Mitigating the risk of African swine fever virus in feed with anti-viral chemical additives. Transboundary and Emerging Diseases. 2021; 68 (2): 477–486. https://doi.org/10.1111/tbed.13699

24. Shurson G. C., Urriola P. E., Schroeder D. C. Biosecurity and mitigation strategies to control swine viruses in feed ingredients and complete feeds. Animals. 2023; 13 (14):2375. https://doi.org/10.3390/ani13142375

25. Shurson G. C., Palowski A., van de Ligt J. L. G., Schroeder D. C., Balestreri C., Urriola P. E., Sampedro F. New perspectives for evaluating relative risks of African swine fever virus contamination in global feed ingredient supply chains. Transboundary and Emerging Diseases. 2022; 69 (1): 31–56. https://doi.org/10.1111/tbed.14174

26. Niederwerder M. C. Risk and mitigation of African swine fever virus in feed. Animals. 2021; 11 (3):792. https://doi.org/10.3390/ani11030792

27. Dee S. A., Bauermann F. V., Niederwerder M. C., Singrey A., Clement T., de Lima M., et al. Survival of viral pathogens in animal feed ingredients under transboundary shipping models. PLoS ONE. 2018; 13 (3):e0194509. https://doi.org/10.1371/journal.pone.0194509

28. Aquilani C., Confessore A., Bozzi R., Sirtori F., Pugliese C. Review: Precision livestock farming technologies in pasture-based livestock systems. Animal. 2022; 16 (1):100429. https://doi.org/10.1016/j.animal.2021.100429

29. Zhang M., Wang X., Feng H., Huang Q., Xiao X., Zhang X. Wearable internet of things enabled precision livestock farming in smart farms:A review of technical solutions for precise perception, biocompatibility, and sustainability monitoring. Journal of Cleaner Production. 2021; 312:127712. https://doi.org/10.1016/j.jclepro.2021.127712

30. Arulmozhi E., Bhujel A., Moon B. E., Kim H. T. The application of cameras in precision pig farming: An overview for swine-keeping professionals. Animals. 2021; 11 (8):2343 https://doi.org/10.3390/ani11082343

31. Benjamin M., Yik S. Precision livestock farming in swine welfare: A review for swine practitioners. Animals. 2019; 9 (4):133. https://doi.org/10.3390/ani9040133

32. Garrido L. F. C., Sato S. T. M., Costa L. B., Daros R. R. Can we reliably detect respiratory diseases through precision farming? A systematic review. Animals. 2023; 13 (7):1273. https://doi.org/10.3390/ani13071273

33. Gu M., Hou B., Zhou J., Cao K., Chen X., Duan C. An industrial Internet platform for massive pig farming (IIP4MPF). Journal of Computer and Communications. 2020; 8 (12): 181–196. https://doi.org/10.4236/jcc.2020.812017

34. Gómez Y., Stygar A. H., Boumans I. J. M. M., Bokkers E. A. M., Pedersen L. J., Niemi J. K., et. al. A systematic review on validated precision livestock farming technologies for pig production and its potential to assess animal welfare. Frontiers in Veterinary Science. 2021; 8:660565. https://doi.org/10.3389/fvets.2021.660565

35. Krugmann K. L., Mieloch F. J., Krieter J., Czycholl I. Investigation of influence of growing pigs’positive affective state on behavioral and physiological parameters using structural equation modeling. Journal of Animal Science. 2020; 98 (2):skaa028. https://doi.org/10.1093/jas/skaa028

36. Dobrovlyanin V. D., Antineskul E. A. Digitalization is developing: the level of digitalization in Russia and the prospects for sustainable development. Digital Models and Solutions. 2022; 1 (2):5. https://doi.org/10.29141/2782-4934-2022-1-2-5 (in Russ.)

37. Koinova A. Avtomatizatsiya i tsifrovizatsiya – klyuch k evolyutsii v svinovodstve = Automation and digitalization – key factors for pig farming evolution. Effectivnoe zhivotnovodstvo. 2020; (8): 66–72. https://www.elibrary.ru/rzpfwz (in Russ.)

38. Smirnova V. V. Digital technologies in pig breeding in Russia. Agrarian Bulletin of the Urals. 2022; (8): 91‒100. https://doi.org/10.32417/19974868-2022-223-08-91-100 (in Russ.)

39. Zhao X., Qi F., Li H., Shi Z. Improving adsorption effect of modified carbon felt on microorganisms in pig houses. Heliyon. 2022; 8 (12):e12418. https://doi.org/10.1016/j.heliyon.2022.e12418

40. Hong S.-W., Park J., Jeong H., Kim M. Evaluation of the microbiome composition in particulate matter inside and outside of pig houses. Journal of Animal Science and Technology. 2021; 63 (3): 640–650. https://doi.org/10.5187/jast.2021.e52

41. Cui H., Zhang C., Liu J., Dong S., Zhao K., Chen L., et al. The distribution characteristics of aerosol bacteria in different types of pig houses. Animals. 2022; 12 (12):1540. https://doi.org/10.3390/ani12121540

42. Lou C., Bai Y., Chai T., Yu H., Lin T., Hu G., et al. Research progress on distribution and exposure risk of microbial aerosols in animal houses. Frontiers in Veterinary Science. 2022; 9:1015238. https://doi.org/10.3389/fvets.2022.1015238

43. Gerunov T. V., Gerunova L. K., Pleshakova V. I., Konev A. V. Opportunistic infections in animals: spread causes and preventive measures. Bulletin of KSAU. 2022; (10): 152–160. https://doi.org/10.36718/1819-4036-2022-10152-160 (in Russ.)

44. Glazunova A. А., Korogodina E. V., Sevskikh T. A., Krasnova E. A., Kukushkin S. A., Blokhin A. A. Reproductive and respiratory syndrome of pigs in pig breeding enterprises (review). Agricultural Science Euro-North-East. 2022; 23 (5): 600–610. https://doi.org/10.30766/2072-9081.2022.23.5.600610 (in Russ.)

45. Aliper T. I., Alekseev K. P., Shemelkov E. V., Verkhovsky O. A., Zaberezhny A. D. The prospect of using marked vaccines against classical swine fever in the Russian Federation. Nauchnye osnovy proizvodstva i obespecheniya kachestva biologicheskikh preparatov: materialy Mezhdunarodnoi prakticheskoi konferentsii, posvyashchennoi 100-letiyu Armavirskoi biofabriki (Armavir, 20–21 avgusta 2021 g.) = Scientific basis of biological product manufacturing and quality assurance: proceedings of the International Practical Conference devoted to the 100th anniversary of the Armavir Biofactory (Armavir, 20–21 August, 2021). Armavir: All-Russian Research and Technological Institute of Biological Industry; 2021; 54–60. https://elibrary.ru/upxsqy (in Russ.)

46. Hung S. W., Chuang C. K., Wong C. H., Yen C. H., Peng S. H., Yang C., et al. Activated macrophages of CD 163 gene edited pigs generated by direct cytoplasmic microinjection with CRISPR gRNA/Cas9 mRNA are resistant to PRRS virus assault. Animal Biotechnology. 2023; 34 (9): 4196–4209. https://doi.org/10.1080/10495398.2022.2062602

47. Lillico S. G., Proudfoot C., King T. J., Tan W., Zhang L., Mardjuki R., et al. Mammalian interspecies substitution of immune modulatory alleles by genome editing. Scientific Reports. 2016; 6:21645. https://doi.org/10.1038/srep21645

About the Authors

A. S. OganesyanRussian Federation

Andrey S. Oganesyan, Cand. Sci. (Veterinary Medicine), Head of Sector, Information and Analysis Centre

Yur’evets, Vladimir 600901, Russia

M. A. Shibayev

Russian Federation

Mikhail A. Shibayev, Cand. Sci. (Veterinary Medicine), Head of Sector, Information and Analysis Centre

Yur’evets, Vladimir 600901, Russia

O. N. Petrova

Russian Federation

Olga N. Petrova, Cand. Sci. (Biology), Deputy Head of the Sector, Information and Analysis Centre

Yur’evets, Vladimir 600901, Russia

N. Ye. Baskakova

Russian Federation

Natalia Ye. Baskakova, Leading Specialist, Information and Analysis Centre

Yur’evets, Vladimir 600901, Russia

A. K. Karaulov

Russian Federation

Аnton К. Karaulov, Cand. Sci. (Veterinary Medicine), Advisor

Yur’evets, Vladimir 600901, Russia

Review

For citations:

Oganesyan A.S., Shibayev M.A., Petrova O.N., Baskakova N.Ye., Karaulov A.K. Situational analysis on porcine diseases of priority to pig industry: methods for biosecurity improvement in the Russian Federation holdings. Veterinary Science Today. 2024;13(4):396-404. https://doi.org/10.29326/2304-196X-2024-13-4-396-404